- Products

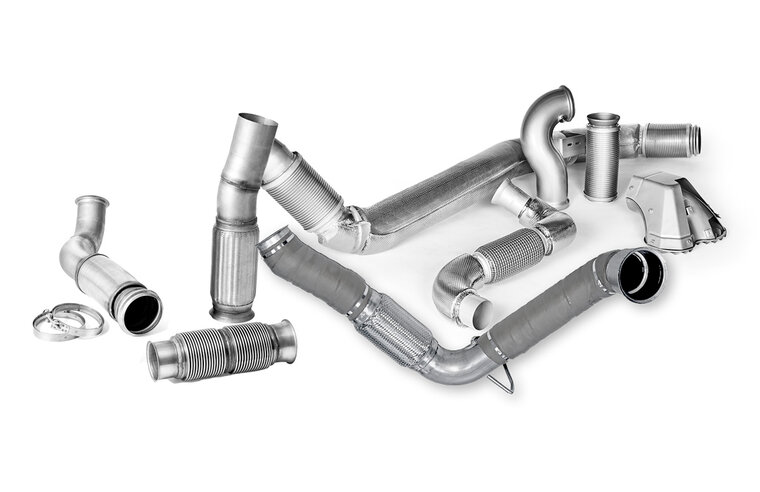

- Exhaust Pipes

Exhaust Pipe Technologies

✔

Manufactured to

OE technologies

✔

409

Stainless Steel

✔

Minimal

Welded Joints

✔

Durable and

Effective Insulation

✔

OE Grade

Bellows and Flex

✔

Full Range and

High Availability

"But isn't that just a pipe?"

For over 40 years, Dinex has been bending and forming exhaust pipes to OE tolerances, using modern production equipment, automotive standard steel grades and applying our own innovative product technologies.

Today, modern exhaust pipes are an integrated part of the Emission Aftertreatment System, which is why compromising quality and performance may end up risky and costly for your business.

Less Welding - More Durability

Pipe bending and direct forming of end-connections directly in the pipe preserves the material's corrosion resistance and leaves you with a stronger product the lasts longer.

That’s why all Dinex pipes come with a solid 3 year warranty (1 year for decoupling elements).

Zachary Holmes, Production Manager at Dinex in Georgia, can explain more about the Dinex-way of making exhaust pipes.

Tightness Against All Odds

From 0 to 1.200°F – across highways and dirt roads.

Exhaust pipes are expected to provide a tight pathway from engine to muffler. But extreme temperature variations and constant vibrations makes this a bit challenging.

Dinex develops and produces its own decoupling elements, and OEMs across the world uses our technology because of the exceptionally low leakage, and leading tolerance to both thermal and physical stress.

Innovation Project Manager, Stanislavs Zilics has developed flex pipes for more than 10 years, and has a bit more to add on this matter. →

Keeping Heat Where It Belongs

The hotter, the cleaner: Successful catalytic reduction of harmful pollutants requires heat. Proper insulation can preserve the temperature of the exhaust gas, which improves catalytic performance and reduces the risk of DEF crystallization.

Dinex’s insulation technologies are tailored for each application and even comes integrated with the pipe's design, making it tough and durable.

Konstantin Bondarev and Aigars Bekmanis both specialize in insulation technologies, and will explain how they are working on both improving existing solutions, and preparing new innovative ones.

You Need Clamps For That?

That which ties it all together is often overlooked – but not at Dinex.

We produce the most important clamps ourselves, because only then can we guarantee the proper fit that you need for a seamless ride for thousands of miles.

And don’t forget: When you replace a pipe, replace the gasket and clamp as well.

Our Product Manager, Rogier van der Ouderaa will explain why this is important. →