- News and events

- News

- Breaking down the CO2 math

Did you read our previous article: “Well-to-Wheel Insights”? Then you have realized that comparing different engines and fuels by simply looking at what comes out of the tail pipe (whether or not the vehicle has one), is a bit like comparing apples and bananas.

For example, did you know that when comparing Battery Electric Vehicles (BEV) with similar Euro 6 diesel vehicles, you will very often find that…

Particulate Pollution from a Battery Electric Vehicle in most cases exceeds that of a diesel?

Why? Because BEVs are typically 25% heavier which causes more wear

of tires, brakes and roads, whereas the diesel has a DPF with a trapping PM

efficiency of over 97%.

NOx emissions per kilometer driven in a Battery Electric Vehicle may exceed those from a diesel?

Why? Because of the fossil fuels being burnt in power plants, supplying

over 60% of the worlds combined grid electricity, whereas a diesel has NOx

an SCR system reducing over 95% of NOx emissions.

Accelerating electrification, faster than decarbonizing grid electricity, may accelerate global warming?

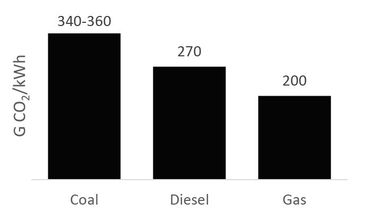

Renewables deliver 4% of the world’s energy needs. Oil is at 35%. Coal, being

25-30% more CO2 intensive than e.g. diesel, is still the main source of electricity.

So, phasing out oil as energy source for vehicles without replacing it with same

amount of renewables may likely result in more coal being burned.

Trucks are not Cars

The calculation we are about to do has been done a dozen times for passenger vehicles. But the everyday commuting to work, dropping off kids at school and grocery shopping trips, are not the same as hauling tons of goods across countries. Longer distances, heavier cargo, and a tight time schedule, means that there are many different aspects we need to consider in order to determine which is more climate friendly.

The scenarios

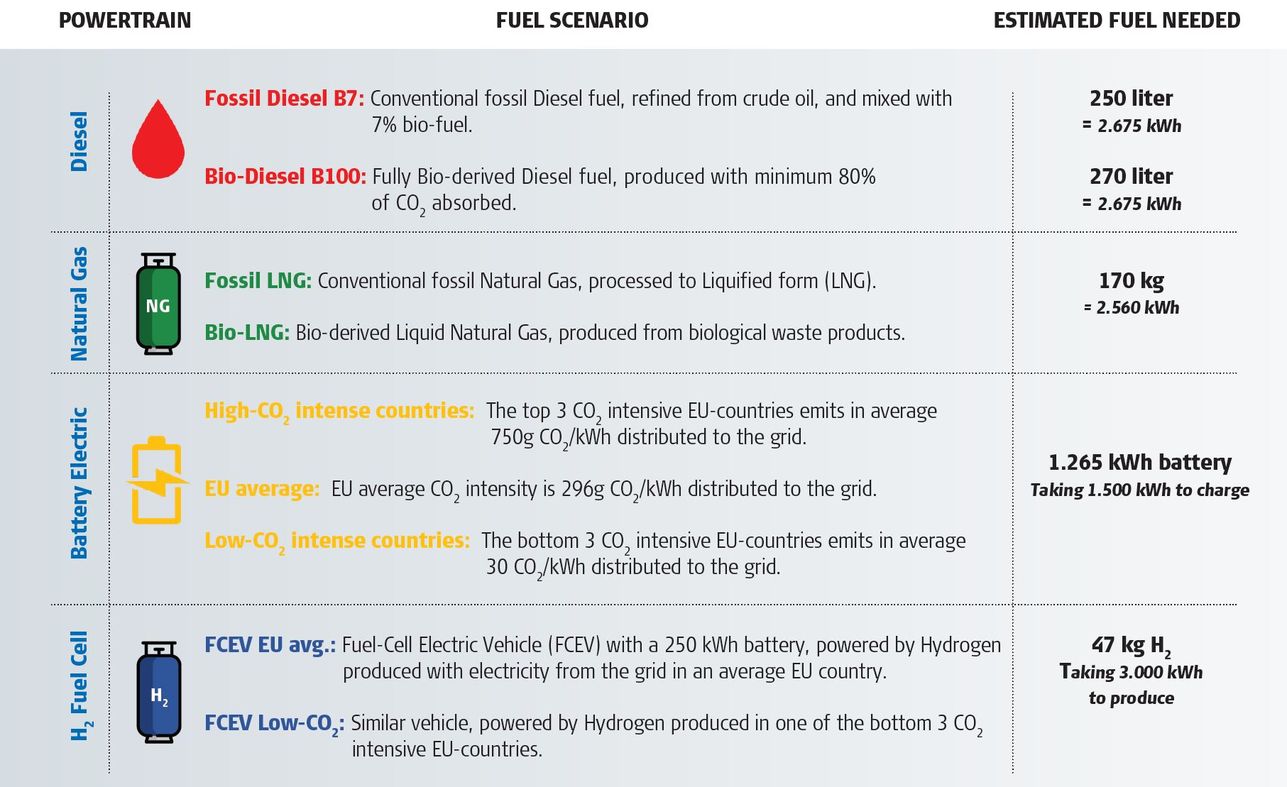

To make a fair comparison, we have put up 9 scenarios, based on 4 different powertrain technologies – all set to do the same job:

Haulage of 40 tons, over a distance of 750 km, at an average speed of 85 km/h.

Diesel and Gas trucks today typically has a range far beyond 750 km, but the driver can only work 9 hours per day, so we estimate that for comparison, this is a sufficient range between fueling/charging.

The net energy required to do this job is 800 kWh, but we need to account for traffic conditions, weather, electric auxiliary systems, heating, etc., so in reality it’s closer to 1.100 kWh. In the end, the gross energy required depends on the energy conversion efficiency, which varies from each technology.

The Battery Dilemma

Before looking at the results, there are 3 factors that should not be ignored for the battery electric powertrains:

Battery degradation: Batteries loose capacity over time. How much and how fast is hard to predict, so in this example we set the battery life to 750.000 km, and adds 25% over-capacity to maintain the 750 km range over the whole life cycle, bringing the full capacity closer to 1.600 kWh.

Battery-production: Production of Lithium-ion batteries for use in electric vehicles typically emit 60-100 kg of CO2eq per kWh of battery capacity. So the 1.600 kWh battery we use in this calculation may very well have emitted 135 tons of CO2eq, before driving it’s first kilometer.

Reduced pay-load: The low energy density of Li-ion batteries means that the 1.600 kWh battery weighs almost 6,5 tons – for the cell alone. With a max vehicle weight of 40 tons, where typically 15 goes for the tractor and the trailer, the Battery-truck will have capacity for over 25% less goods, compared to a Diesel or Gas truck.

Well-to-Wheel and LifeCycle emissions

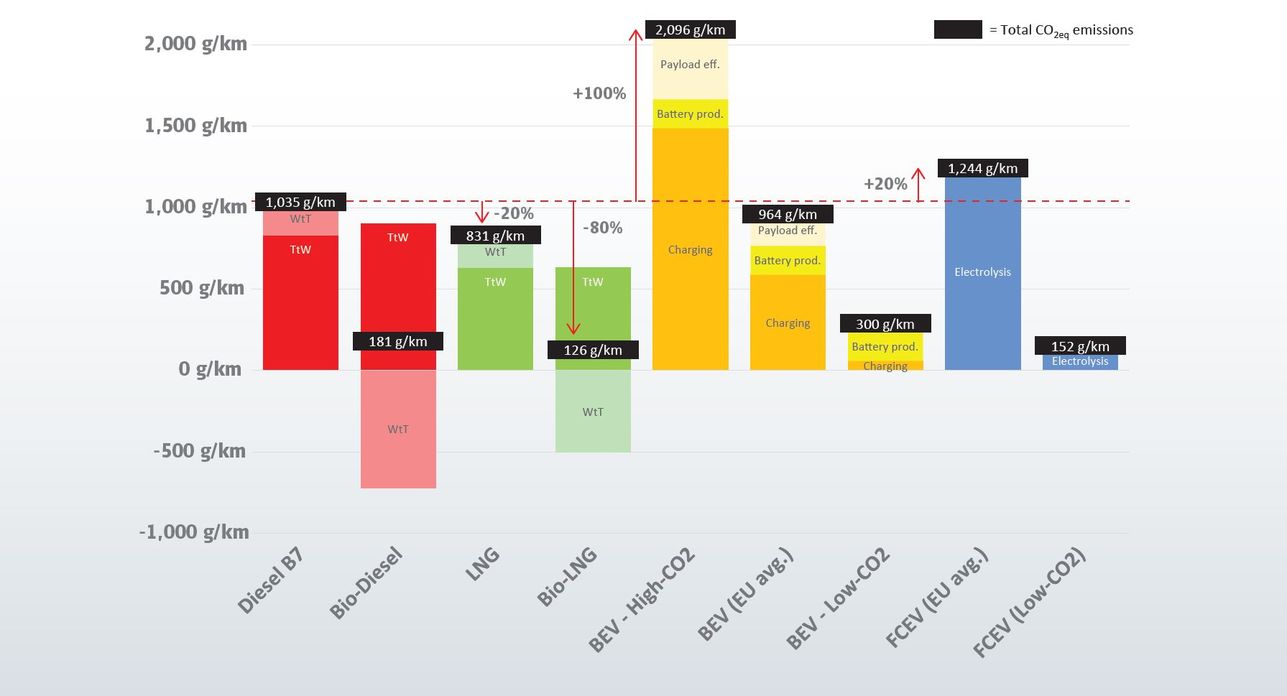

The first visualization of the results clearly shows the differences in WtW emissions per kilometer driven in the 9 different scenarios. As traditional diesel is today the dominant fuel for powering commercial vehicles, let’s consider this as the baseline.

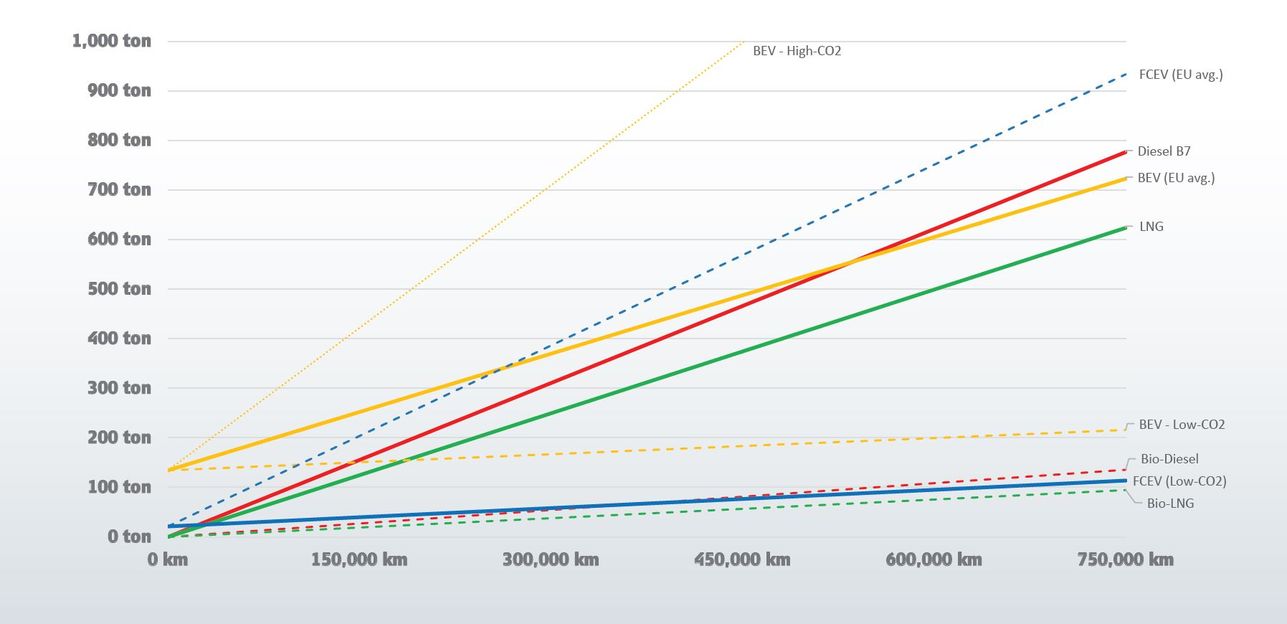

The second visualization takes a more LifeCycle-based approach, demonstrating clearly the effect of the CO2 intense battery production. We see here especially the effect of the battery production. Notice that even though the electric truck has a 7% less CO2/km advantage over the diesel-truck, when powered by EU average grid electricity per km. driven, it takes over 500.000 km of operation before battery production effect is offset.

The Take-Aways

Analyzing the results, it is clear that combustion engine powertrains are not necessarily “dirtier” than electric powertrains. We would like to highlight 4 main take-aways from this study:

Natural Gas emits 20% less CO2 than B7 Diesel

The higher energy content and engine efficiency, combined with a cleaner combustion and lower noise levels, and a price tag significantly below EVs and Hydrogen powertrains, makes commercial CNG and LNG vehicles a highly attractive alternative to diesel for use in urban areas and regions with a well developed re-fueling network and beneficial tax systems.

Bio-fuels offers instant CO2 reduction for existing fleets

The availability of high-quality bio-fuels is growing. The market is expanding, and the potential is huge. The majority of existing Diesel and Gas powered vehicle can already operate on much higher bio-blends than in use today – many even up to 100% – meaning the Well-to-Wheel CO2 impact could be reduced up to 90% - simply by switching the fuel.

EVs are extremely volatile to the energy mix

Depending on the source of the electricity, an EV can be anything from twice as “dirty”, to 85% cleaner than a diesel. The world’s availability of sustainable energy is growing, but there is still a long way to go, and the calculation shows that any CO2 intensity above 300 g/kWh makes a traditional Diesel truck more favorable in terms of CO2 emissions.

The Hydrogen Fuel Cycle suffers from low energy efficiency

It takes 3 kWh of electric energy to produce enough Hydrogen to generate 1 kWh of energy at-the-wheels of a Fuel Cell vehicle – the rest is wasted through the complex processes. So, this only makes sense if the fuel is produced by sustainable energy - and even then, only if it is available in sufficient excess. Until then, it might be worth considering if that energy is put to better use distributed to the grid, replacing coal and other fossil sources of electricity.

The conclusion?

All 4 technologies has the potential of being nearly CO2 neutral – it’s a question of how they are fueled, and it is clear that with the energy mix today, EVs and FCEVs are only feasible for the climate in limited scenarios, and specific parts of the world, where certain prerequisites exists.

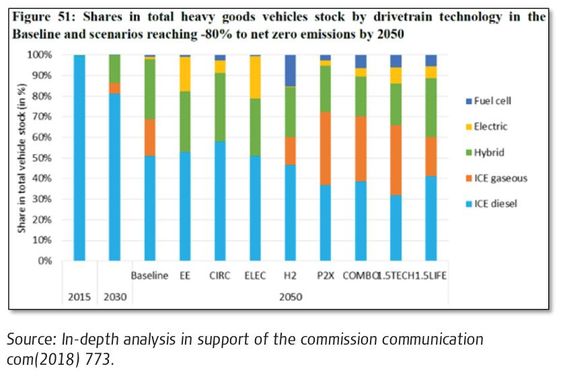

In 2018 the European Commission presented 8 scenarios as to how 80-100% CO2 neutrality can be achieved in 2050, and for heavy duty transportation none of them relied on a single powertrain technology, but a diversified combination of all applied where they make sense – still dominated by Diesel, Gas and Hybrids.

While alternative powertrain technologies still are relatively immature, the diesel engine has a history of over a 100 years of innovation, leading to continuous improvements and refinement. A modern diesel-truck operates today at an energy efficiency up to 40%, and the industry has demonstrated roadmaps for how to increase this to 50-55% within a foreseeable future - simply by continuing the already ongoing innovation.

The Internal Combustion Engines should be considered as a part of the solution to our climate challenges, instead of a part of the problem. There is still much more that can be done to pick-up on the last 100 years of innovation, and at Dinex we are fully prepared for post-Euro VI emission standards, that will set new benchmarks for NOx emissions, cold-start performance, and more efficient filters.

For 30 years global emission norms have driven technological innovation of exhaust aftertreatment solutions to a level where modern Euro VI-d heavy duty engines are now “cleaner than the air you breathe” – and we’re working for an even cleaner tomorrow.

Questions or comments?

Kristian Kaufmann / +45 63412648 / krk@dinex.dk